Dental thermal sealers

To preserve the sterility of the instruments - an absolute must in dentistry - Anthos provides a range of thermal sealers that combine ease of use with outstanding reliability. These devices ensure proper sealing of the packaged material, thus guaranteeing long-lasting sterility of dental instruments in compliance with the relevant standards.

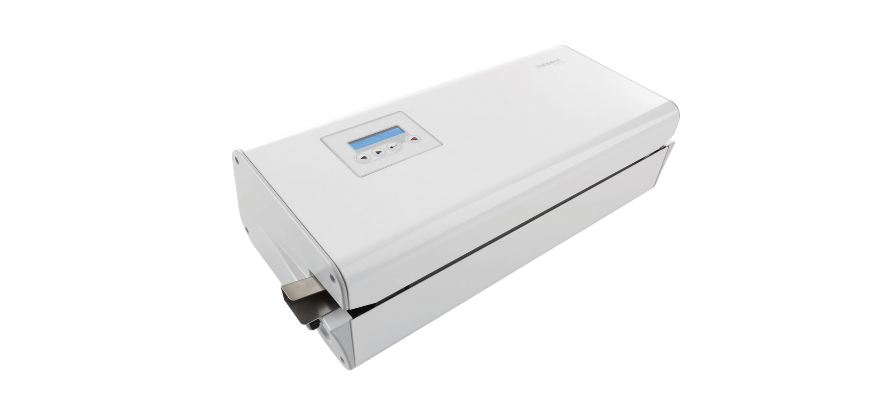

Millseal+ Evo

Automatic version: Millseal+ Evo is able to manage the entire material packaging procedure, from preparation of the pouches to their final sealing. Motorized adjustment of pouch length ensures maximum precision, thus optimising paper consumption.

A programme for every need

The machine has two operating programmes, P1 and P2. These allow the operator to customise the pouch length and quantity parameters. Once one of the two programs has been selected and started, the machine automatically prepares pouches, sealed at one end, of the desired length and quantity. This feature saves the practice a significant amount of time by automating a traditionally long, demanding operation. Note, however, that the device can still be used in manual mode via the user-friendly keypad.

Practical display

Programme selection is simple and immediate. Operating parameters are kept under control at all times thanks to the large display showing the selected settings (length and number of pouches) for the pouch preparation procedure.

Guaranteed sterilization

Millseal+ Evo dental thermal sealers are equipped with electronic parameter control (time and sealing temperature) and guarantee a 12 mm wide sealing band, well in excess of legal requirements Furthermore, visual-acoustic messages provide information on sealer efficiency.

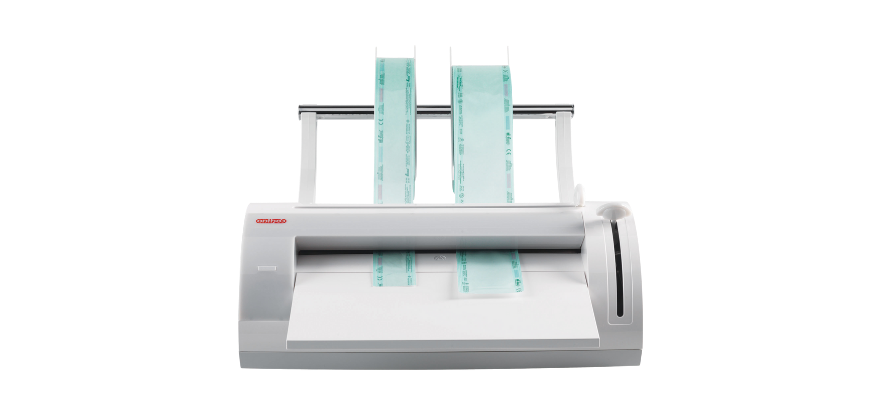

Millseal+ Manual

The Millseal+ Manual dental thermal sealer allows the operator to freely select the length of the pouch, cut it and seal it using simple manual procedures. A confirmation beep guarantees the quality and consistency of the sealing process.

Consistent performance

Automatic temperature adjustment ensures fine heating control of the sealing bar, maintaining long-lasting high quality performance. What’s more, the thermal sealer also features an overheating protection system and an automatic energy-saving standby mode.

Practical ergonomic design

The machine is designed to optimise use of space by maximising the number of paper rolls managed while minimising the surface area occupied on the work top. The positioning system keeps the paper in place and prevents rewinding of the roll after cutting and sealing, providing a linear, uninterrupted procedure.

Easier pouch management

The roll holder allows up to three rolls to be housed simultaneously, with a maximum width of 300 mm. Roller changeovers are fast and user-friendly.

Millseal Rolling

This automatic-feed thermal sealer is optimal for speeding up the sealing procedure on pouches pre-cut and sealed on three sides. Temperature is adjusted via a keypad; operating parameters are shown on the LCD display.

Innovative technology

The 15 mm sealing multiband ensures long-lasting sterility of packaged instruments. Thanks to temperature adjustment, it’s possible to control the sealing action, ensuring consistently high performance over time.

Automatic drive and photocell

The entire packaging procedure can be executed automatically: a photocell allows precision control of automatic on-roller pouch transit.

Integrated printer

Millseal Rolling can be used in conjunction with a printer to print packaging and expiry dates or symbols required by the standards in force.

Are you a practitioner or a dealer?

Need more details about our products? Would you like to receive personalised advice or find out which solutions best suit your needs? The Anthos team is ready to respond.

-1.png)